Filter and sort

What are submersible pumps and what are they used for?

Submersible pumps are devices designed to operate fully submerged in water, converting electrical energy (solar, DC or AC) into hydraulic energy to deliver flow and pressure from wells, boreholes, tanks, and bodies of water. They cover domestic supply, irrigation, livestock, water transfer, and high-head applications. In this collection you will find Lorentz PS2 (with integrated MPPT controller), Grundfos SQFlex, ZIRI, Shurflo 9325, and Acrosun. The Lorentz PU units (pumps without controller) are listed as spare parts and are not part of this product collection.

Advantages and limitations

- High water columns: helical hydraulics (screw) perform well at high heads with medium flows; centrifugal pumps prioritize flow at low to medium heads.

- Solar efficiency: systems with MPPT controller (e.g., Lorentz PS2 or SQFlex with control unit) optimize daily photovoltaic production.

- Reliability: encapsulated motors, non-return valve, and durable materials (stainless steel/technopolymers).

- Limitations: require correct hydraulic/electrical sizing, minimum filtration in water with sediments, and protection against dry running.

Subfamilies in the collection

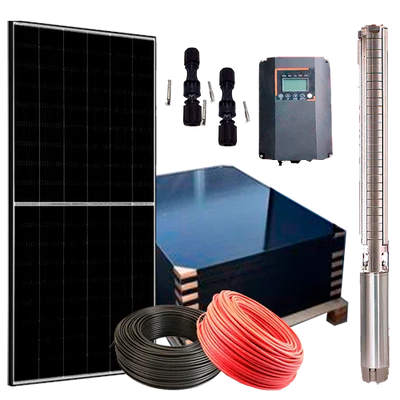

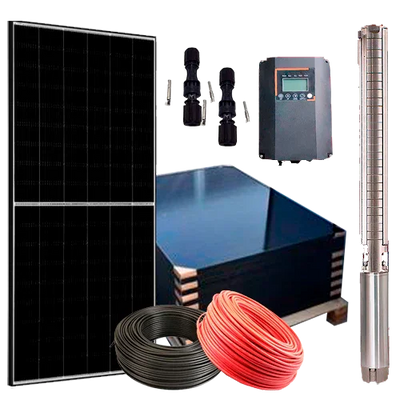

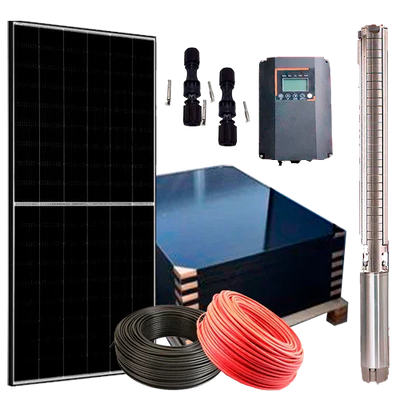

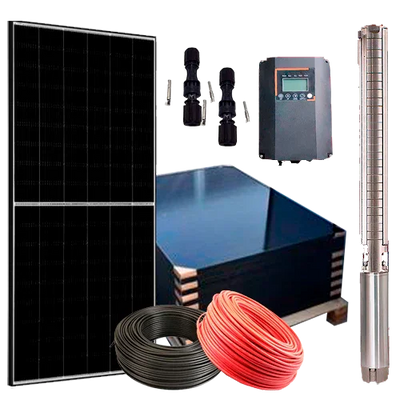

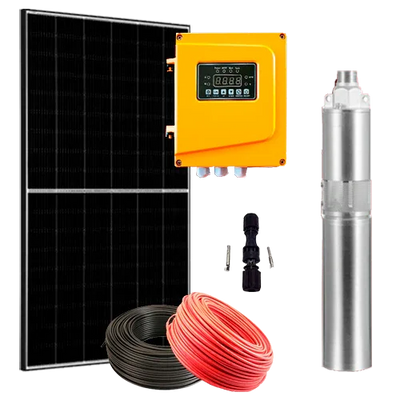

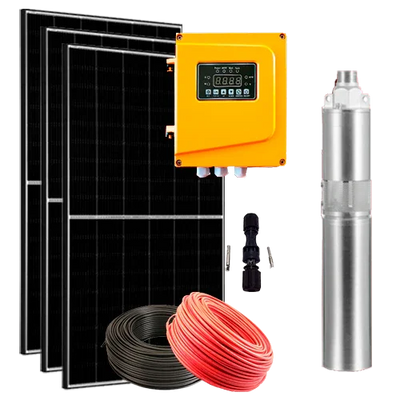

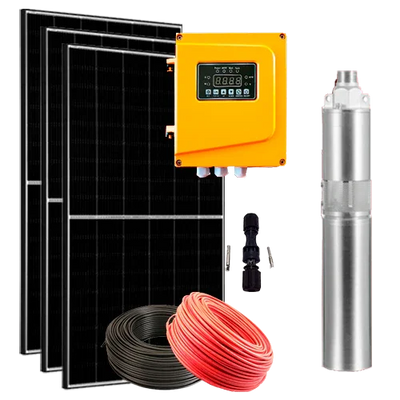

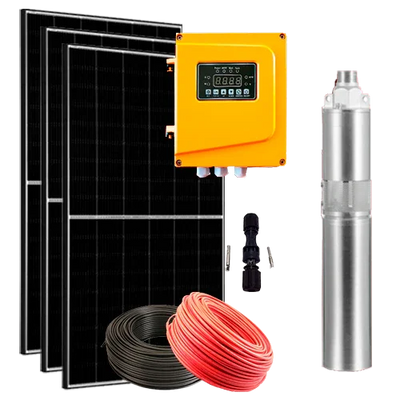

- Solar Submersible Pumps: PV panels + controller/inverter, ideal for off-grid.

- Hybrid Submersible Pumps: switch between solar and 230 V for service continuity.

- AC Submersible Pumps: recommended when grid or generator is available.

How to choose your submersible pump

- Operating point: flow (m³/h) and Total Manometric Head (TMH, m) = geodetic height + losses (pipe, elbows, valves, filters).

- Power source: solar with MPPT (already included in PS2), 12/24/48 V DC or 230 V AC.

- Hydraulics: centrifugal for high flows/low-medium heads; helical for high columns with moderate flow.

- Borehole diameter: 3" or 4" depending on casing; check tolerances for body, cable, and joints.

- Water quality: install minimum filtration if there are sediments; in brackish water, prioritize 316 stainless steel and suitable seals.

- Protections: well probe, pressure switch/press-control (if there is an intermediate tank), non-return valve, and DC surge protection.

Indicative technical specifications

| Typical flow | 0.4–78 m³/h depending on series and diameter |

| Manometric head | 10–450 m (helical for extreme heights) |

| Power supply | Direct solar MPPT / 12–24–48 V DC / 230 V AC |

| Hydraulics | Centrifugal | Helical |

| Pump diameter | 3" and 4" (check borehole casing) |

| Protections | Non-return, thermal, dry running, DC surge |

Best installation practices

- Select by flow–head curve of the model, not by catalog maximums.

- Size piping and cable section to minimize losses and voltage drops.

- Install a non-return valve on the discharge and level probes to protect against dry running.

- For solar, coordinate PV power, controller, and motor limits; respect maximum cable lengths.

- Maintenance plan: check connections, clean filters, and verify insulation.

Related collections and accessories

If you later need to pressurize the internal network, visit Pressure Pumps. For transfers without immersion, see Surface Pumps. For pool recirculation, go to Pool Filters. Complete with Accessories (PS2/CU controllers, probes, protections, filters) and find individual units and parts in Spare Parts.