Filter and sort

What are structures for ground and flat roof?

They are support systems that allow the installation of photovoltaic modules on horizontal surfaces (flat roofs and ground), providing controlled tilt, stability against wind/snow, and load evacuation paths without compromising waterproofing. Within the family of structures for solar panels, these solutions are based on benches with triangles, aerodynamic bases and/or distributed ballasts, and are complemented by specific accessories.

Advantages and limitations

- Maximum performance: allows adjustment of the angle (e.g., 10–30º) to optimize annual production.

- Installation without drilling (depending on the system): option with ballast to preserve the watertightness of the roof.

- Speed and repeatability: modular kits in aluminium with predefined joints.

- Versatility: south orientation or East/West configuration to reduce height and wind loads.

- Limitations: the weight of the ballast and the distances to the edge must be calculated; on lightweight roofs, mechanical fixing or reinforcements may be required.

Applications

- Residential and tertiary buildings with flat roofs of concrete, gravel, or membrane.

- Industrial and commercial: large surfaces with East/West layout for better power density.

- Ground mounting: driven or ballasted benches for self-consumption, pumping, or small-scale plants.

How to choose the right solution

- Support and admissible load: check the structural capacity of the roof and the additional weight per m² (ballast + structure).

- Fixing strategy: ballast only (without drilling), mixed (ballast + anchors), or mechanical fixing with certified pipe penetrations.

- Angle and orientation: south for annual peak, or East/West for more useful hours and lower row height.

- Wind zoning: perimeters and corners require greater fixing/ballast; respect setbacks.

- Module compatibility: frame height, distance between supports, and manufacturer’s clamps.

Typical specifications

| Materials | Structural aluminium and A2/A4 stainless steel fasteners |

| Solutions | Inclined triangles, aerodynamic bases, benches for East/West, driven/ballasted on ground |

| Tilt range | Approximately 5º–35º depending on model and load calculation |

| Fixing to support | Distributed ballast, mechanical fixing with pipe penetrations or mixed, depending on waterproofing |

| Frame compatibility | Intermediate/end clamps for standard frames (≈30–40 mm) |

| Calculation standards | Wind/snow Eurocodes and manufacturer’s technical guides |

Best practices

- Carry out a load calculation considering wind zone, building height, and obstacles.

- Protect the membrane with rubber bases or separating sheets; avoid puncturing.

- Define setbacks to the edge and maintenance paths; align rows to limit shading.

- In East/West, control the spacing between rows and the height to reduce wind suction.

- Route cabling through trays and secure it with UV ties; use certified pipe penetrations if there are penetrations.

Comparisons

- Ground/Flat vs Coplanar: greater freedom of angle and irradiation, in exchange for greater wind exposure and need for ballast or fixing.

- Ground/Flat vs Metal roof: does not depend on sheet crests/valleys; prioritizes waterproofing and load distribution.

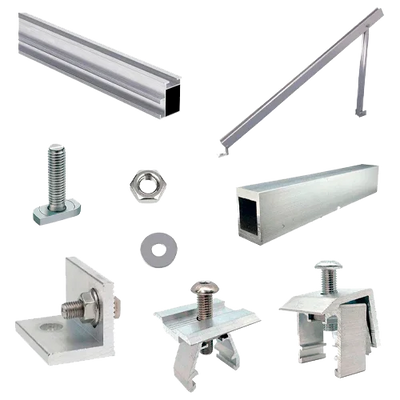

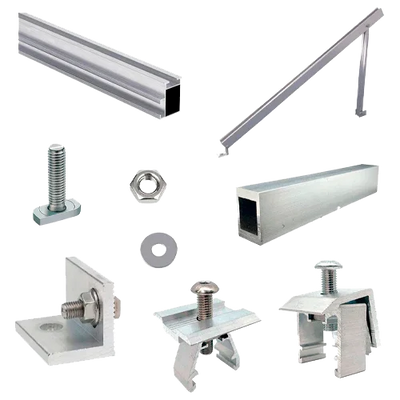

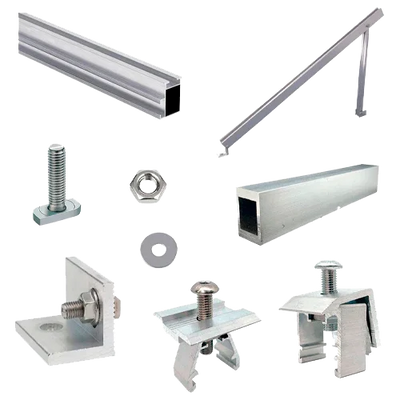

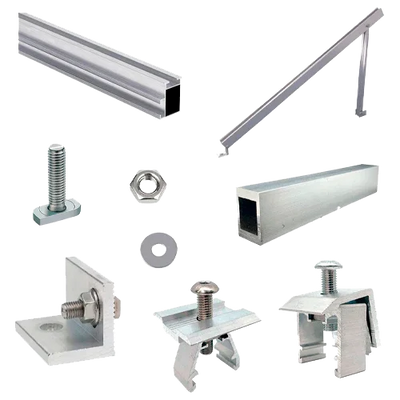

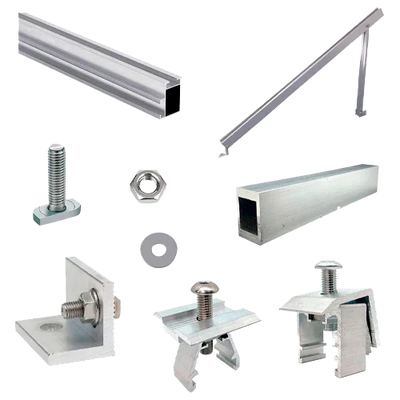

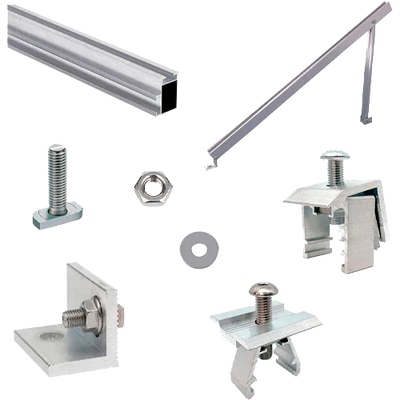

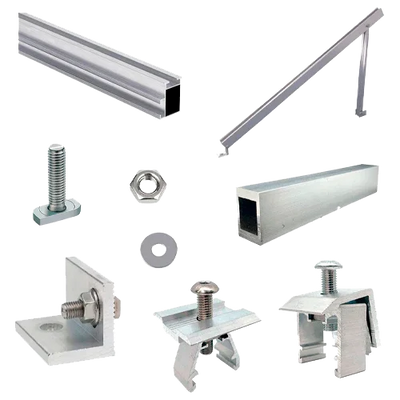

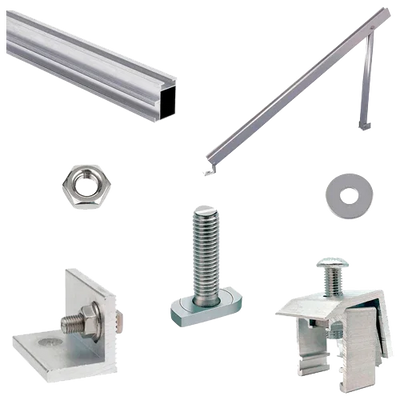

Related accessories

Complete your project with clamps, joints, rails, wind stops, and fasteners. For a global overview by type of support, see Structures for Solar Panels.