Filter and sort

What are structures for metal roofs?

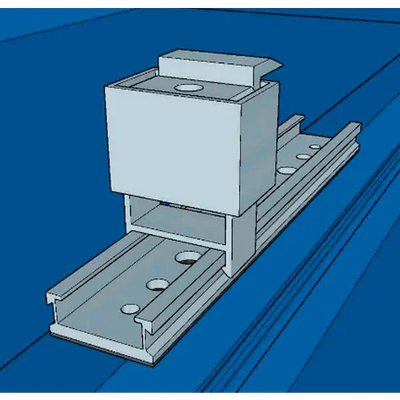

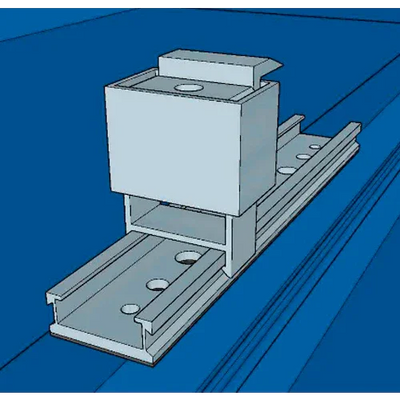

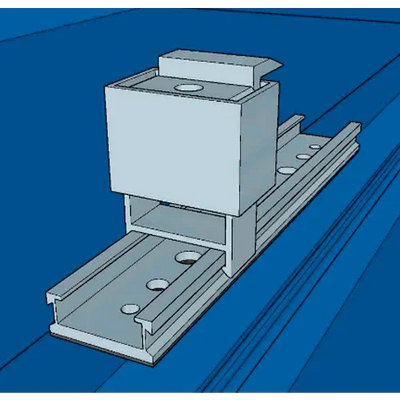

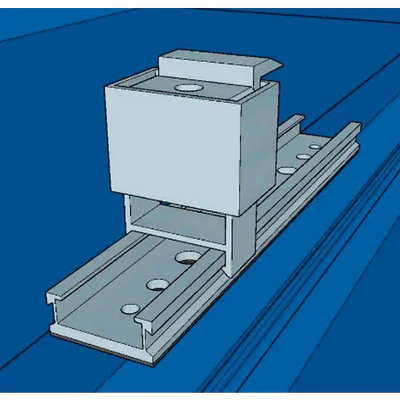

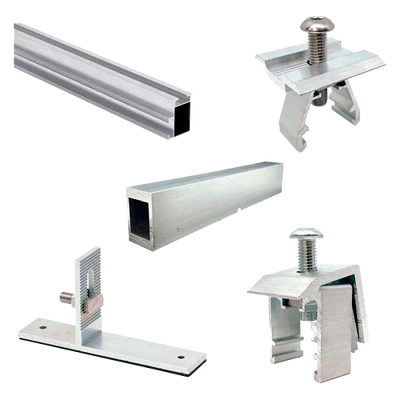

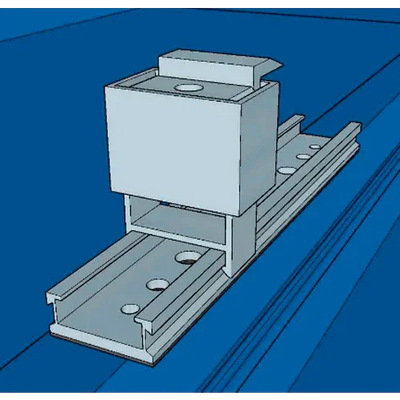

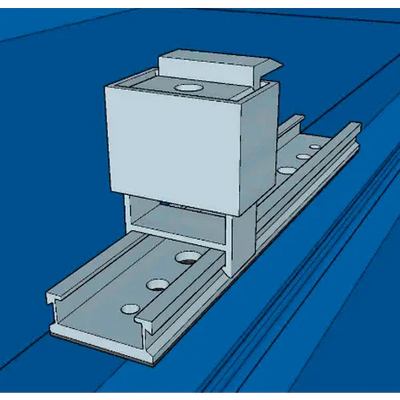

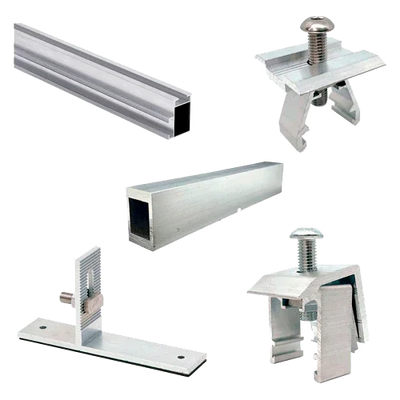

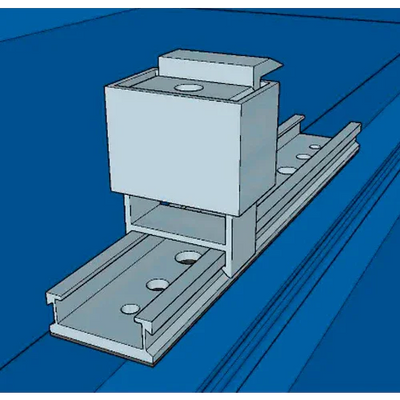

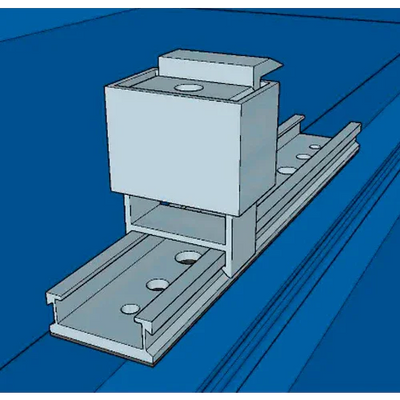

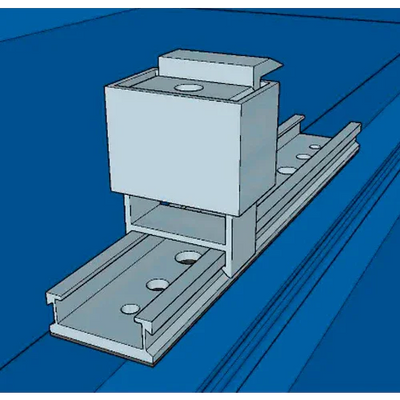

They are fastening systems designed to install photovoltaic modules on trapezoidal sheets and sandwich panels, safely transferring wind and snow loads to the building’s substructure. They use clamps and self-drilling screws with EPDM gaskets, or specific clamps for standing seam joints, preserving watertightness. This subfamily is part of Structures for Solar Panels and is complemented by Accessories for Structures.

Advantages and limitations

- Quick installation: direct fastening to sheet crests with drilling templates and lightweight rails.

- Guaranteed watertightness: EPDM washers and specific accessories for sandwich panels.

- Structural lightness: aluminium and stainless steel reduce self-weight and corrosion.

- Versatility: solutions for trapezoidal, corrugated profiles and roofs with standing seam.

- Limitations: requires correct identification of the profile type and sheet thickness to select suitable screws and tightening torque.

Applications

- Industrial and logistics buildings with trapezoidal sheet or sandwich panel.

- Agri-food facilities and farms with lightweight metal roofs.

- Car parks and metal canopies with standard profiles.

How to choose the right solution

- Type of roof: trapezoidal, sandwich or standing seam. Select a clamp/support compatible with the profile.

- Thickness and material: define the self-drilling screw (tip, thread and length) and whether pre-drilling is required.

- Wind zoning: perimeters and corners require higher anchor densities.

- Module geometry: frame height (≈30–40 mm) and support spacing according to manufacturer’s datasheet.

- Load path: always anchor to purlins/structural bracing; avoid deteriorated sheets.

- Alternatives: if the roof is pitched with tile or slate, consider Coplanar Structures; for flat surfaces, Flat Roof and Ground.

Typical specifications

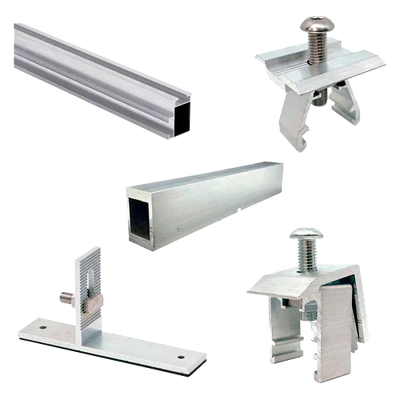

| Materials | Structural aluminium profiles; screws and clamps in A2/A4 stainless steel |

| Sealing | EPDM washers and base plates shaped to the sheet profile |

| Compatibility | Trapezoidal/corrugated profiles and sandwich panels of steel or aluminium |

| Module fastening | End and mid clamps, usual frame height 30–40 mm |

| Design standards | Eurocodes (wind/snow) and manufacturer’s guidelines for tightening torques |

| Maintenance | Periodic inspection of screws and joints; retightening as per plan |

Best practices

- Identify the sheet profile and measure crest/valley to choose compatible bases.

- Use self-drilling screws with controlled torque; do not crush the EPDM washer.

- Respect edge setbacks and increase anchors at corners according to wind calculation.

- Arrange rails in a direction that minimises stresses and facilitates thermal expansion.

- Route elevated cabling with UV clips and watertight cable glands when necessary.

Comparisons

- Metal roof vs coplanar on tile: sheet allows quick drilling and lower self-weight; tile requires hooks and greater attention to waterproofing the structure.

- Metal roof vs flat/ground: on metal, lightness and speed are prioritised; on flat/ground, tilt is optimised and ballast may be required.

Related accessories

Complete the installation with clamps, joints, rails, screws and wind stops. For an overview by support type, visit the main collection Structures for Solar Panels.